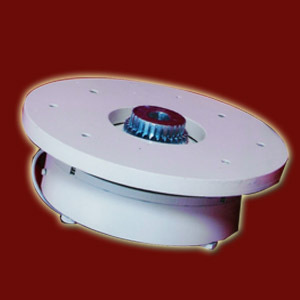

Electro Magnetic Brake

Electro Magnetic Brake Specification

- Part Type

- Brake Assembly

- Mounting Type

- Flange Mount

- Noise Level

- Low

- Features

- Compact Design, High Efficiency, Fast Response

- Usage & Applications

- Industrial Machines, Conveyors, Lifts & Elevators

- Brake Type

- Electro Magnetic Brake

- Size

- 150 mm

- Material

- Cast Iron

- Pattern Material

- Aluminium

- Surface Finish

- Powder Coated

- Standard

- ISI Certified

- Weight

- 5 Kg

- Coil Material

- Copper

- Ambient Humidity

- Max 90% RH

- Input Voltage

- 24V DC

- Torque Capacity

- 6 Nm

- Duty Cycle

- S1 Continuous

- Insulation Class

- Class F

- Power Consumption

- 18 Watts

- Thermal Protection

- Yes

- Release Time

- 30 ms

- Temperature Range

- -20°C to +80°C

- Protection Class

- IP54

Electro Magnetic Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Delivery Time

- 1 Week

- Packaging Details

- Wooden box packing available.

- Main Domestic Market

- All India

About Electro Magnetic Brake

Established in the year 1965, we are an eminent manufacturer, exporter and supplier of a wide range of Electro Magnetic Brake SLDC Series. The provided series is manufactured using fine quality raw materials and advanced machines under the supervision of our skilled team of professionals. Offered series is used in steel plants to stop rotating machinery like motor or gearbox. Our offered Electro Magnetic Brake SLDC Series can be availed from us in number of specifications at economical prices.

Key Features:

- Easy to install

- Durability

- Corrosion resistance

- Robust construction

Reliable Performance Under Demanding Conditions

Designed to function smoothly from 20C to +80C and in environments with up to 90% relative humidity, this electromagnetic brake ensures consistent performance for industrial, conveyor, and elevator setups. The powder-coated cast iron housing and copper coil construction contribute to its durability and efficiency, while the advanced thermal protection increases operational safety.

Quick Release and High Efficiency

Featuring a rapid response time of just 30 milliseconds, the brake minimizes downtime during emergency or routine stops. Its 6 Nm torque capacity and S1 continuous duty cycle make it ideal for applications requiring frequent engagement. The IP54 protection class adds resilience in dusty or moist operating environments, while the compact, flange mount design supports easy integration into existing systems.

FAQs of Electro Magnetic Brake:

Q: How does the electromagnetic brake ensure safe and quick operation in industrial applications?

A: The brake uses electromagnetic force to provide a fast 30 ms release time, offering immediate response during emergency and routine stops. Its S1 continuous duty cycle and integrated thermal protection ensure reliable performance even during prolonged use, making it ideal for industrial machinery, conveyors, and elevators.Q: What are the advantages of a flange mount design for installation?

A: A flange mount allows for easy and secure installation onto machinery, ensuring proper alignment and stable operation. This design is compatible with various industrial equipment, simplifies the mounting process, and helps reduce setup time.Q: Where is this electromagnetic brake typically used?

A: This brake is commonly used in industrial machines, conveyors, lifts, and elevators. Its robust construction and quick response make it suitable for applications requiring precise stopping and holding under varying environmental conditions.Q: What process is involved in the operation of this brake assembly?

A: When the 24V DC voltage is applied to the copper coil inside the brake, it generates an electromagnetic field that disengages the brake. Once voltage is removed, spring force engages the brake, stopping or holding the load. This process allows rapid engagement and release with minimal power consumption.Q: When should maintenance be performed on this brake?

A: Routine maintenance should follow manufacturer recommendations or be scheduled at regular intervals depending on the operational environment and usage frequency. Proper inspection ensures the brake remains in optimal condition, especially in environments with high dust or humidity.Q: What is the benefit of having ISI certification and IP54 protection class?

A: ISI certification assures compliance with Indian quality and safety standards, while IP54 protection means the brake is guarded against dust ingress and water splashes, making it reliable in harsh industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electro Magnetic Brake Category

Electromagnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Smooth Painted

Noise Level : Low

Features : Quick response, compact design, low maintenance

Mounting Type : Flange Mount

Standard : IS: 8654

Industrial Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated/Painted

Noise Level : Less than 70 dB

Features : High Torque, Quick Response, Robust Construction, Efficient Heat Dissipation, Fail Safe Operation

Mounting Type : Foot Mounted

Standard : IS: 47761 and 2/IEC

Fail Safe Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated

Noise Level : Low

Features : High Torque, Quick Response, Reliable Performance, Easy Maintenance

Mounting Type : Flange Mounted

Standard : IS: 3642

Industrial Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated

Noise Level : Low Noise Operation

Features : High Torque, Fast Response, Durable Construction, Easy Maintenance

Mounting Type : Flange Mounting

Standard : IS 9537

Send Inquiry

Send Inquiry