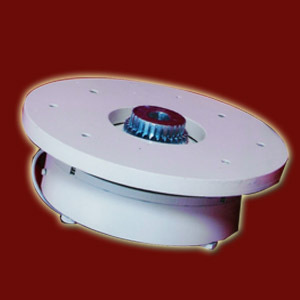

Electromagnetic Brake

Electromagnetic Brake Specification

- Part Type

- Brake Assembly

- Usage & Applications

- Industrial machinery, crane hoists, automation equipment

- Noise Level

- Low

- Mounting Type

- Flange Mount

- Features

- Quick response, compact design, low maintenance

- Brake Type

- Electromagnetic

- Size

- 6 inch

- Material

- Cast Iron

- Pattern Material

- High Grade Steel

- Surface Finish

- Smooth Painted

- Standard

- IS: 8654

Electromagnetic Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Packaging Details

- Wooden box packing available.

- Main Domestic Market

- All India

About Electromagnetic Brake

We are an unparalleled name in offering premium quality Electromagnetic Brake - MB-Series. This series is manufactured under the stern direction of our adroit professionals using supreme quality raw materials in accordance with the set norms of the industry. Our provided series offers excellent overload and jam protection and also ensures soft start with zero slip when a preset torque is reached. In order to meet the diverse needs of our prestigious clients, offered Electromagnetic Brake - MB-Series is made available in different specifications at highly reasonable prices.

Features:

- Fine finish

- Easy installation

- Elevated durability

- Impact proof

Reliable Stopping Power

Designed to ensure quick and precise stopping, this electromagnetic brake achieves a holding torque of 10 Nm and releases smoothly within 30 milliseconds. Such responsiveness safeguards machinery and enhances process control.

Durable, Low-Maintenance Construction

Manufactured with a robust cast iron body and high-grade steel pattern components, this brake assembly features an anti-corrosive enamel finish and copper-wound coil. It promises longevity with minimal maintenance, making it a dependable choice for demanding applications.

Versatile Performance Standards

Compliant with IS: 8654 standards, the brake operates across a wide voltage input24V DC or 220V ACcatering to diverse installation requirements in Indian industry. Its design supports high-cycle environments with over a million operational cycles expected.

FAQs of Electromagnetic Brake:

Q: How is the electromagnetic brake installed and connected electrically?

A: The brake features a flange mounting system and is equipped with a terminal box for electrical connections. This ensures straightforward integration with industrial setups operating on either 24V DC or 220V AC power supply.Q: What makes this brake suitable for industrial machinery and automation equipment?

A: Its fast release time, compact design, 10 Nm holding torque, and low power consumption (18 watts) make it ideal for applications that require reliable and frequent braking, such as crane hoists and automated machinery.Q: When should I consider replacing or servicing the brake assembly?

A: With a life cycle exceeding one million operations and low maintenance needs, regular inspections according to your maintenance schedule are sufficient. Replace or service if you notice performance inefficiencies or mechanical wear beyond specifications.Q: Where can this electromagnetic brake be used, given its temperature and humidity range?

A: The brake operates efficiently in ambient conditions from -10C to +60C and humidity up to 90% RH, making it suitable for a wide variety of indoor industrial environments in India.Q: What benefits does the anti-corrosive enamel coating provide?

A: The anti-corrosive enamel coating protects the brake assembly against rust and environmental damage, extending its service life and ensuring consistent performance even in harsh conditions.Q: How does the electromagnetic brake achieve quick response and low noise?

A: The combination of copper-wound coil, precision manufacturing, and a smooth painted surface finish allows for rapid activation and release with minimal noise, enhancing operator comfort and machinery efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electro Magnetic Brake Category

Fail Safe Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Pattern Material : Other, NonAsbestos

Part Type : Electro Magnetic Brake Assembly

Brake Type : Other, Fail Safe Electro Magnetic Brake

Material : Steel

Surface Finish : Other, Powder Coated

Industrial Magnetic Brake

Minimum Order Quantity : 1 Piece

Pattern Material : Other, Friction Lined Shoes (Asbestos/NonAsbestos)

Part Type : Disc/Shoe Brake Unit

Brake Type : Other, Electromagnetic Shoe Brake

Material : Cast Iron Body with Copper Coil

Surface Finish : Other, Powder Coated/Painted

Industrial Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Pattern Material : Other, Copper Wound Coil

Part Type : Complete Brake Assembly

Brake Type : Other, Electro Magnetic Brake

Material : Cast Iron

Surface Finish : Other, Powder Coated

Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Pattern Material : Other, Aluminium

Part Type : Brake Assembly

Brake Type : Other, Electro Magnetic Brake

Material : Cast Iron

Surface Finish : Other, Powder Coated

Send Inquiry

Send Inquiry