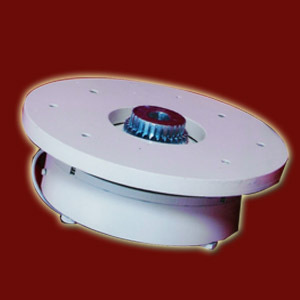

Fail Safe Electro Magnetic Brake

Fail Safe Electro Magnetic Brake Specification

- Mounting Type

- Flange Mounted

- Usage & Applications

- Hoists, Cranes, Elevators, Conveyors, Winches, Textile Machinery

- Noise Level

- Low

- Part Type

- Electro Magnetic Brake Assembly

- Features

- High Torque, Quick Response, Reliable Performance, Easy Maintenance

- Brake Type

- Fail Safe Electro Magnetic Brake

- Size

- 120 mm to 250 mm

- Material

- Steel

- Pattern Material

- Non-Asbestos

- Surface Finish

- Powder Coated

- Standard

- IS: 3642

Fail Safe Electro Magnetic Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Delivery Time

- 1 Week

- Packaging Details

- Wooden box packing available.

- Main Domestic Market

- All India

About Fail Safe Electro Magnetic Brake

We are a trusted name amongst the leading manufacturer, exporter and supplier of Fail Safe Electro Magnetic Brake - DAT-Series to our widely spread clients. It makes use of premium grade raw material procured from reliable vendors of the industry associated with us for year. Our team of experts conduct various quality checks to ensure adherence of our Fail Safe Electro Magnetic Brake- DAT-Series to the prevailing standards of the industry.

Reliable Fail Safe Technology

Engineered with fail safe technology, this electro magnetic brake guarantees automatic engagement during power loss, preventing equipment from unintentional movement. Reliability is maximized by high-quality copper coil material and a design validated for over one million operations, making it a trusted choice for industrial safety.

Versatile Torque and Voltage Options

With torque capacities available from 4 Nm up to 250 Nm and compatibility with 24V DC, 190V DC, and 230V AC supplies, the brake assembly fits a wide spectrum of machinery. Its flexibility ensures optimal performance and easy integration into various systems across multiple industries in India.

FAQs of Fail Safe Electro Magnetic Brake:

Q: How does the Fail Safe Electro Magnetic Brake function during a power failure?

A: In case of a power loss, the electromagnetic brake automatically engages its braking action, bringing equipment to a halt. This fail safe mechanism ensures safety by preventing unintended movement, making it ideal for critical operations such as hoists, cranes, and elevators.Q: What are the typical applications for this electro magnetic brake?

A: This brake is widely used in hoists, cranes, elevators, conveyors, winches, and textile machinery. Its high torque, quick response, and reliable performance make it suitable for continuous duty in various industrial and commercial environments.Q: When should this brake be considered for installation?

A: You should consider installing this brake when operational safety is paramount, especially in applications where unpredictable power interruptions may occur. It is also recommended for equipment requiring high torque and rapid stopping capability.Q: Where can this brake be mounted, and is it easy to maintain?

A: The fail safe brake is designed for flange mounting, which allows easy integration into different machinery setups. Maintenance is straightforward due to its robust construction and powder-coated steel finish, requiring minimal intervention over its long operational lifespan.Q: What benefits does the use of copper coil provide in this brake system?

A: Copper coils enhance the electrical efficiency and heat dissipation of the brake, supporting continuous-duty cycles and ensuring consistent performance under varying load conditions. This choice of material contributes to the brakes reliability and longevity.Q: How does the brake ensure low noise and quick response during operation?

A: The advanced design combines non-asbestos friction material with precise engineering, enabling fast release times between 10-50 ms and maintaining a low noise level. This ensures minimal disturbance to surroundings and responsive operation, crucial for sensitive or high-traffic applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electro Magnetic Brake Category

Electromagnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Smooth Painted

Brake Type : Other, Electromagnetic

Usage & Applications : Industrial machinery, crane hoists, automation equipment

Features : Quick response, compact design, low maintenance

Standard : IS: 8654

Industrial Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated

Brake Type : Other, Electro Magnetic Brake

Usage & Applications : Industrial Machinery, Cranes, Elevators, Conveyors

Features : High Torque, Fast Response, Durable Construction, Easy Maintenance

Standard : IS 9537

Industrial Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated/Painted

Brake Type : Other, Electromagnetic Shoe Brake

Usage & Applications : Material Handling Equipment, Cranes, Hoists, Conveyors, Industrial Machines

Features : High Torque, Quick Response, Robust Construction, Efficient Heat Dissipation, Fail Safe Operation

Standard : IS: 47761 and 2/IEC

Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Powder Coated

Brake Type : Other, Electro Magnetic Brake

Usage & Applications : Industrial Machines, Conveyors, Lifts & Elevators

Features : Compact Design, High Efficiency, Fast Response

Standard : ISI Certified

Send Inquiry

Send Inquiry