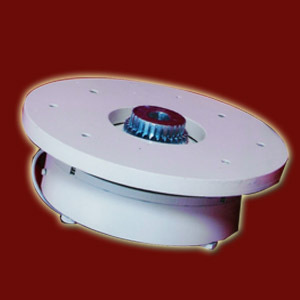

Industrial Magnetic Brake

Industrial Magnetic Brake Specification

- Part Type

- Disc/Shoe Brake Unit

- Features

- High Torque, Quick Response, Robust Construction, Efficient Heat Dissipation, Fail Safe Operation

- Mounting Type

- Foot Mounted

- Usage & Applications

- Material Handling Equipment, Cranes, Hoists, Conveyors, Industrial Machines

- Noise Level

- Less than 70 dB

- Brake Type

- Electromagnetic Shoe Brake

- Size

- 200 mm to 500 mm (customizable sizes available)

- Material

- Cast Iron Body with Copper Coil

- Pattern Material

- Friction Lined Shoes (Asbestos/Non-Asbestos)

- Surface Finish

- Powder Coated/Painted

- Standard

- IS: 4776-1 and 2/IEC

- Coil Duty

- Continuous

- Brake Torque

- Up to 2000 Nm (as per model)

- Weight

- 15 kg - 70 kg based on size

- Duty Cycle

- S1/S2 (Continuous and Short Time Duty)

- Insulation Class

- Class F / Class H

- Release Method

- Electromagnetic Release Spring Applied

- Operating Temperature

- -20°C to +50°C

- Voltage

- 415V AC / 220V DC (custom design possible)

- Protection Rating

- IP54/IP55

Industrial Magnetic Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Cash in Advance (CID)

- Delivery Time

- 1 Week

- Packaging Details

- Wooden box packing available.

- Main Domestic Market

- All India

About Industrial Magnetic Brake

We are one of the noteworthy manufacturers, exporters and suppliers engaged in offering technologically advanced Magnetic Brake. This brake is manufactured by our adroit professionals using superior grade raw material and the progressive technology as per the defined industry norms to confirm its durability. Offered magnetic brake finds its application in roller coasters and railroad trains, in which the metallic conductor has the shape of a linear rail. Also, this brake finds application in automobile and railway industries. Furthermore, offered Magnetic Brake can be availed from us at nominal rates.

Features:

-

Rust resistance

-

Accurate dimensions

-

Durability

-

High strength

Superior Performance and Customization

Designed to meet diverse industrial requirements, this brake offers high torque, quick response, and efficient heat dissipation. Custom design options empower users to select suitable sizes, voltages, and pattern materials, ensuring an optimal fit for material handling equipment, cranes, hoists, and more. The powder coated or painted finish, combined with IP54/IP55 ingress protection, guarantees lasting durability across challenging operational environments.

Reliable Electromagnetic Safety

Featuring an electromagnetic release with spring-applied mechanism, this brake provides dependable fail-safe operation. It ensures minimal noise (below 70 dB), robust construction, and continuous coil duty for both continuous (S1) and short-term (S2) workloads. The cast iron body and copper coil optimize efficiency, while friction lined shoes provide secure stopping power, contributing to enhanced equipment safety and longevity.

FAQs of Industrial Magnetic Brake:

Q: How does the electromagnetic release spring-applied mechanism benefit industrial safety?

A: The electromagnetic release spring-applied mechanism ensures that the brake stays engaged in the event of power failure, providing a fail-safe solution. This significantly enhances safety for material handling equipment, cranes, and conveyors, as machinery stops instantly and securely if electrical supply is interrupted.Q: What are the advantages of using cast iron body and copper coil in this industrial magnetic brake?

A: The cast iron body delivers durability and robust construction, while the copper coil ensures excellent conductivity and efficient electromagnetic performance. This combination enhances heat dissipation and overall reliability, supporting demanding industrial environments.Q: When is it advisable to use insulation Class F or Class H for this brake?

A: Insulation Class F is suitable for most general industrial applications, offering reliable protection up to 155C. Class H is recommended for situations with higher ambient temperatures or elevated thermal loads, supporting operations up to 180C, thereby extending brake life in more challenging conditions.Q: Where can these magnetic brakes be installed?

A: These brakes are ideal for installation in material handling systems, cranes, hoists, conveyors, and other industrial machinery. Their foot-mounted design and customizable sizes accommodate various machine layouts, ensuring seamless integration in both new and retrofit projects.Q: What is the process for selecting the appropriate model and voltage specification?

A: Selection involves evaluating required brake torque (up to 2000 Nm), duty cycle (continuous S1 or short-time S2), suitable voltage (415V AC or 220V DC), and environmental conditions. Custom designs are available to fit particular machine or operational needs, ensuring optimal performance and compatibility.Q: How does efficient heat dissipation enhance brake performance and longevity?

A: Efficient heat dissipation prevents overheating during continuous or heavy-duty use, maintaining the integrity of copper coils and friction materials. This ensures sustained braking efficiency, minimizes maintenance requirements, and extends the operational life of the brake system.Q: What benefits does compliance with IS: 4776-1 & 2/IEC standards bring?

A: Compliance with these standards ensures that the brake meets established safety, performance, and quality benchmarks. It offers peace of mind to users regarding product reliability, safety in operation, and compatibility with international industrial practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electro Magnetic Brake Category

Electromagnetic Brake

Minimum Order Quantity : 1 Piece

Brake Type : Other, Electromagnetic

Size : 6 inch

Features : Quick response, compact design, low maintenance

Pattern Material : Other, High Grade Steel

Surface Finish : Other, Smooth Painted

Industrial Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Brake Type : Other, Electro Magnetic Brake

Size : 150 mm to 400 mm

Features : High Torque, Fast Response, Durable Construction, Easy Maintenance

Pattern Material : Other, Copper Wound Coil

Surface Finish : Other, Powder Coated

Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Brake Type : Other, Electro Magnetic Brake

Size : 150 mm

Features : Compact Design, High Efficiency, Fast Response

Pattern Material : Other, Aluminium

Surface Finish : Other, Powder Coated

Fail Safe Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Brake Type : Other, Fail Safe Electro Magnetic Brake

Size : 120 mm to 250 mm

Features : High Torque, Quick Response, Reliable Performance, Easy Maintenance

Pattern Material : Other, NonAsbestos

Surface Finish : Other, Powder Coated

Send Inquiry

Send Inquiry