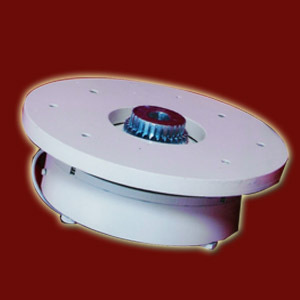

Industrial Electro Magnetic Brake

Industrial Electro Magnetic Brake Specification

- Usage & Applications

- Industrial Machinery, Cranes, Elevators, Conveyors

- Noise Level

- Low Noise Operation

- Part Type

- Complete Brake Assembly

- Features

- High Torque, Fast Response, Durable Construction, Easy Maintenance

- Mounting Type

- Flange Mounting

- Brake Type

- Electro Magnetic Brake

- Size

- 150 mm to 400 mm

- Material

- Cast Iron

- Pattern Material

- Copper Wound Coil

- Surface Finish

- Powder Coated

- Standard

- IS 9537

Industrial Electro Magnetic Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Delivery Time

- 1 Week

- Packaging Details

- Wooden box packing available.

- Main Domestic Market

- All India

About Industrial Electro Magnetic Brake

As an eminent enterprise, we manufacture, export and supply an exclusive range of Industrial Electro Magnetic Brake DC Series that is mainly used in heavy duty vehicles. Manufactured by utilizing premium quality components as per the latest market trends, the offered series is designed as per the standards penciled by the industry. Our provided series assures high durability and resistant against corrosion. This Industrial Electro Magnetic Brake DC Series is available in diverse specifications to fulfill the varied needs of our valuable clients.

Features:

- Easy installation

- Less maintenance

- Smooth operation

- Robust construction

Reliability in Critical Applications

The electromagnetic brake is purpose-built to serve varied industrial sectors including cranes, elevators, industrial machinery, and conveyors. With rigid construction, flange mounting, and an IP54 protection class, it ensures dependable performance and longevity under continuous (S1), intermittent (S2), or short-time (S3) duty cycles, even in harsh working environments.

Precision and Efficiency

Delivering actuation times of less than 50 milliseconds and available torque ratings from 10 Nm to 400 Nm, these brakes guarantee precise, responsive stopping and holding capabilities. Asbestos-free linings and powder-coated finishes support low-maintenance and safe operation while maintaining minimal operational noise.

FAQs of Industrial Electro Magnetic Brake:

Q: How does the manual release provision function on the electromagnetic brake?

A: The manual release provision allows operators to disengage the brake manually during power outages or maintenance. This feature provides enhanced safety and convenience in situations where electrical actuation is unavailable.Q: What makes this electromagnetic brake suitable for industrial applications?

A: Its robust cast iron construction, high torque capacity, fast response under 50 ms, and IP54 protection ensure reliable operation in heavy-duty environments such as cranes, elevators, and conveyor systems. It is engineered for easy maintenance and long operational life.Q: When should I use S1, S2, or S3 duty cycles with this brake?

A: Select the duty cycle based on your applications operational needs: S1 for continuous operation, S2 for short-time working, and S3 for intermittent duty. This flexibility ensures optimal brake performance and efficiency in varied industrial setups.Q: Where is this electromagnetic brake typically installed?

A: These brakes are commonly flange-mounted directly onto machinery, elevators, cranes, or conveyor systems. Their adaptable sizes (150 mm to 400 mm) and mounting flexibility support diverse installation requirements.Q: What benefits does the asbestos-free friction lining provide?

A: Asbestos-free friction lining enhances operator and environmental safety while maintaining reliable braking power and durability. It ensures compatibility with modern health and safety standards.Q: How is power consumption determined for each model?

A: The brakes power consumption varies between 16 and 40 watts, depending on its torque rating and size. The optimal model is selected based on the braking force required by your specific industrial application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electro Magnetic Brake Category

Electromagnetic Brake

Minimum Order Quantity : 1 Piece

Mounting Type : Flange Mount

Surface Finish : Other, Smooth Painted

Pattern Material : Other, High Grade Steel

Features : Quick response, compact design, low maintenance

Brake Type : Other, Electromagnetic

Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Mounting Type : Flange Mount

Surface Finish : Other, Powder Coated

Pattern Material : Other, Aluminium

Features : Compact Design, High Efficiency, Fast Response

Brake Type : Other, Electro Magnetic Brake

Industrial Magnetic Brake

Minimum Order Quantity : 1 Piece

Mounting Type : Foot Mounted

Surface Finish : Other, Powder Coated/Painted

Pattern Material : Other, Friction Lined Shoes (Asbestos/NonAsbestos)

Features : High Torque, Quick Response, Robust Construction, Efficient Heat Dissipation, Fail Safe Operation

Brake Type : Other, Electromagnetic Shoe Brake

Fail Safe Electro Magnetic Brake

Minimum Order Quantity : 1 Piece

Mounting Type : Flange Mounted

Surface Finish : Other, Powder Coated

Pattern Material : Other, NonAsbestos

Features : High Torque, Quick Response, Reliable Performance, Easy Maintenance

Brake Type : Other, Fail Safe Electro Magnetic Brake

Send Inquiry

Send Inquiry